Household Appliances

Innovative Solutions for Household Appliances:

Our high-performance insulation enables household appliances such as refrigerators, freezers, and ovens to operate more energy-efficiently. Energy consumption is significantly reduced, and usable volume is increased. This allows appliances to achieve top efficiency classes while maintaining a compact design.

Efficient Insulation for Household Appliances

Household appliances need to reliably cool, freeze, wash, or heat — while saving energy. va-Q-tec combines vacuum insulation panels (VIPs) with phase change materials (PCMs) to deliver maximum insulation performance with minimal wall thickness.

The result: more interior space, lower energy consumption, and reduced operating costs — especially for refrigerators, freezers, ovens, and dishwashers. Efficiency, comfort, and sustainability “Made in Germany.”

Products

Maximum Efficiency

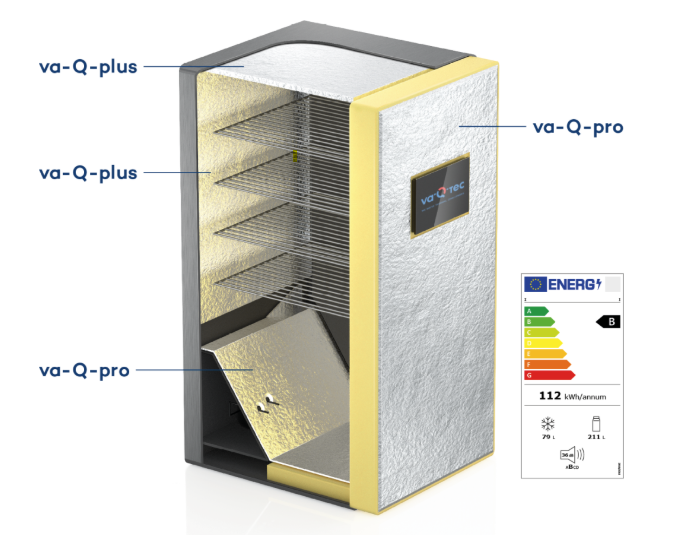

va-Q-tec achieves this through intelligent thermal management using vacuum insulation panels (VIPs) and phase change materials (PCMs). The high-tech insulation provides maximum surface coverage, as even complex areas such as compressor compartments or irregular geometries can be insulated with VIPs. This allows significantly better insulation performance at the same material thickness or, conversely, more usable interior space at the same insulation effect.

As a result, energy consumption and costs for the end user are noticeably reduced, while more space is created inside the appliance. This advantage is particularly evident in refrigerators and freezers, but VIPs and PCMs also help reduce energy usage and improve sustainability in ovens and dishwashers.

Development & Implementation Support

To develop optimal solutions, va-Q-tec supports projects from the initial inquiry through to series production. The expertise consolidated in our Thermal Engineering Center provides support at every stage, from concept and implementation to quality assurance.

Benefits of va-Q-tec High-Performance Insulation

Our vacuum insulation panels (VIPs) are redefining the standards in refrigeration technology. From household appliances and laboratory equipment to industrial cooling systems, we provide solutions that excel both technically and economically:

Since the tightening of EU labelling requirements in 2021, insulation performance has become the critical success factor. VIPs reduce heat loss so drastically that top ratings (energy class A or B) often only become technologically feasible through their integration.

Compared to conventional insulation materials such as PU foam or mineral wool, VIPs offer reduced material thickness while providing the same insulation performance. This allows the walls of equipment or containers to be made considerably slimmer. The space gained by the thinner insulation layer is directly available as additional usable volume.

Yes. Our panels are based on pyrogenic silica – a mineral raw material that poses no health risks. In addition, va-Q-tec VIPs are almost completely recyclable at the end of their long service life, making them the preferred choice for sustainable appliance platforms.

Yes. Thanks to its superior insulation performance, the temperature on the surface of the device is stabilised and the dew point is reliably shifted to the outside. This reliably prevents condensation from forming – even in conditions of high humidity or extreme temperature differences – thereby protecting the housing and integrated electronics.

Yes. Thanks to va-Q-pro technology, we manufacture VIPs in almost any 2D or 3D freeform shape. This means that even complex areas such as compressor niches, door constructions or ice dispensers can be thermally optimised. This allows the VIP surface coverage to be increased from the standard 65% to up to 85% – a decisive lever for overall efficiency.

Additional Business Areas of va-Q-tec

In addition to commercial equipment, va-Q-tec offers comprehensive solutions across various industries. Our portfolio includes, among others, pharmaceutical logistics in the last-mile pharma segment, where we provide specialized packaging for temperature-sensitive medications. For the automotive industry, we develop innovative solutions for transport logistics. In the chemical sector, we ensure the safe handling and transport of chemicals under controlled conditions. Furthermore, we offer tailored solutions for the food industry to guarantee the safe and energy-efficient transport of temperature-sensitive products.