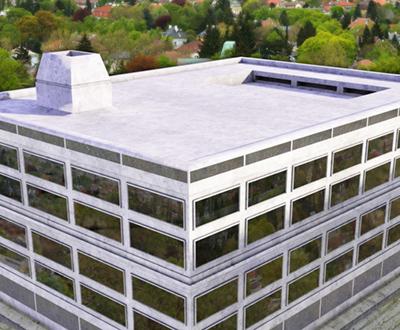

Construction

Your expert for building insulation solutions

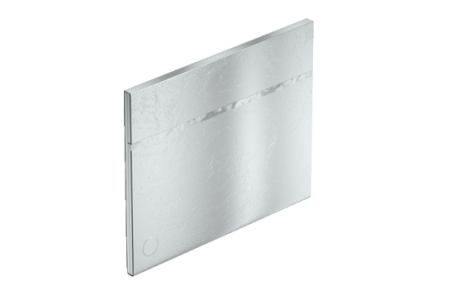

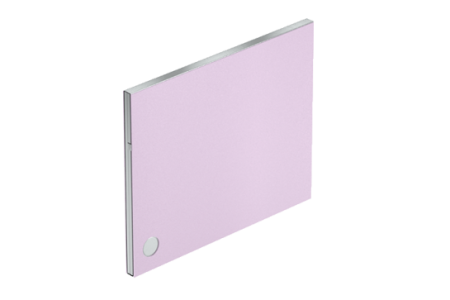

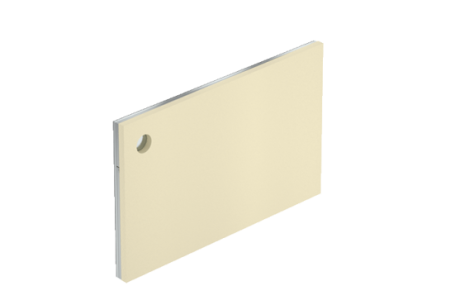

As a pioneer in the vacuum insulation sector, va-Q-tec develops innovative insulation solutions for new constructions and renovations. Based on Vacuum Insulation Panels (VIPs), the products provide a high level of insulation, greatly reduced insulation thickness and modular construction for different sizes and shapes. They are particularly advantageous in locations that offer small space but still require good thermal insulation. All va-Q-tec products are the result of intensive development.

They provide added value to customers and offer solutions for basic social challenges like energy conservation. The high product quality, controlled by the worldwide unique and patented va-Q-check® control system, enables the reliable application of

this durable, highly efficient vacuum insulation.