Commercial Appliances

Innovative Solutions for Commercial Appliances

In continuous commercial operation, reliability and cost efficiency are critical success factors. Whether high-performance coffee machines or modern vending machines, today’s appliances must handle high volumes while simultaneously meeting stringent sustainability targets.

Precise Temperature Control, Slim Design

va-Q-tec solutions address these requirements with maximum precision. Our Vacuum Insulation Panels (VIPs) significantly reduce heat losses at extremely slim wall thicknesses, thereby lowering energy demand during standby operation.

In addition, our Phase Change Materials (PCMs) compensate for temperature fluctuations and ensure stable thermal conditions. Measurable Efficiency Gains in Daily Operation

The result is higher energy efficiency, extended service life, and measurable cost-saving potential in daily use – in gastronomy, retail, and beyond.

Cost Reduction Through the Use of VIPs:

- 30% lower daily energy consumption in real operating conditions

- 30% energy savings in standby mode due to reduced heat losses

- >20% less energy per cup during the brewing process

- 10% savings according to standard measurements – with significantly higher potential in real-life operation

Products

Maximum Efficiency Through Precise Thermal Management

va-Q-tec solutions are designed to meet the highest requirements for energy efficiency and temperature stability.

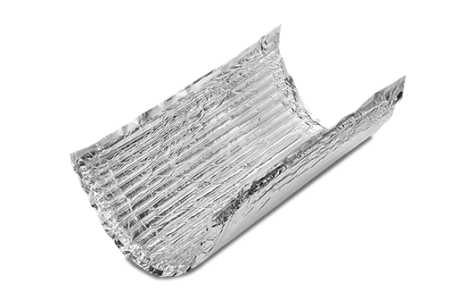

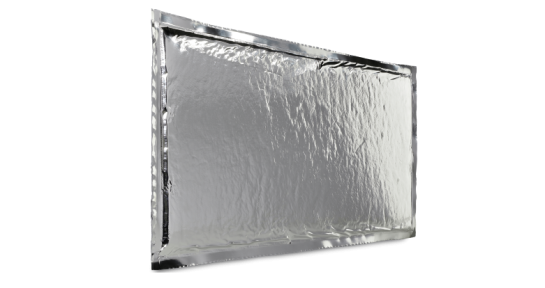

Vacuum Insulation Panels (VIPs) minimize heat losses with extremely slim wall thicknesses and significantly reduce energy consumption during standby operation.

Phase Change Materials (PCMs) compensate for temperature fluctuations and ensure stable thermal conditions.

Especially in applications such as professional coffee machines and vending machines, precise temperature control, higher efficiency, and long service life translate into measurable cost savings and operational advantages.

These benefits also apply to many other commercial applications in gastronomy and retail.

Further Applications in Commercial Environments

In addition to coffee machines and vending machines, many other professional appliances operate under continuous heavy use every day. Whether in gastronomy, retail, or large-scale kitchens, consistent temperatures, high energy efficiency, and reliable performance are essential. The use of VIPs and PCMs opens up additional opportunities: energy losses are reduced, processes are stabilized, and the lifespan of the equipment is extended.

Refrigerated Cabinets

Refrigerated furniture is a central element in gastronomy and retail. It must keep food consistently at low temperatures, even when the units are frequently opened. VIPs reduce heat loss despite their slim design, creating more usable interior space. Additionally, PCMs stabilize the temperature by buffering short-term fluctuations when doors are opened. The result is lower energy costs and consistently high product quality.

Commercial Refrigerators

Professional refrigerators in kitchens or canteens operate continuously and are often exposed to challenging conditions such as heat and high humidity. The combination of VIPs and PCMs reduces energy consumption, extends compressor cycles, and thereby minimizes wear. Operators benefit from lower operating costs and increased reliability of the equipment.

Dishwashers

Efficient thermal insulation also plays a crucial role in dishwashers. These appliances operate at high temperatures, which are quickly lost without proper insulation. VIPs minimize heat loss while maintaining a compact design, and PCMs store heat to ensure more stable processes. As a result, energy consumption per wash cycle is reduced, and the appliances more easily meet stringent efficiency standards.

Development & Implementation Support

To ensure optimal results, va-Q-tec supports projects from the initial concept to series production.

All expertise is bundled in the Thermal Engineering Center, providing professional support at every project stage – from design to quality assurance.

Advantages of va-Q-tec High-Performance Insulation

Our vacuum insulation panels (VIPs) are redefining the standards in refrigeration technology. From household appliances and laboratory equipment to industrial cooling systems, we provide solutions that excel both technically and economically:

In many commercial applications, such as professional coffee machines, the investment often pays for itself within a year. While standby losses are reduced by up to 30%, the energy requirement per brewing process is reduced by over 20% – a massive lever for reducing ongoing operating costs.

VIPs ensure a stable internal temperature and reliably protect the contents from extreme external influences. This applies both to high ambient temperatures caused by direct sunlight in summer and to low temperatures and frost in winter. At the same time, they reduce the energy consumption of vending machines, for example, by up to 45% and ensure compliance with strict EU efficiency directives.

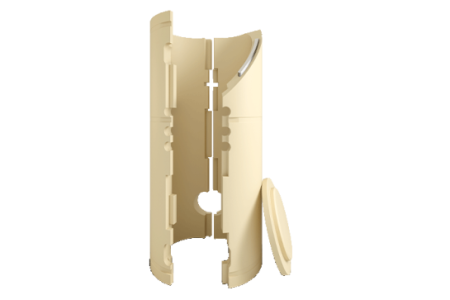

Thanks to their low material thickness and va-Q-pro free-form technology, VIPs can usually be integrated without any fundamental changes to existing product designs or manufacturing processes. They often serve as a “minimally invasive” plug-and-play upgrade for critical thermal zones such as compressor niches.

Massive energy savings directly reduce the CO₂ emissions of equipment fleets. This not only improves the sustainability balance sheet of manufacturers and operators, but also contributes positively to the green brand image and the achievement of global climate targets (ESG).

Absolutely. With va-Q-steel, we offer special solutions for temperature ranges up to +400 °C. These significantly reduce the energy consumption of ovens, enable more compact exterior designs and ensure increased user safety thanks to a cooler exterior (“cool touch”).

Additional va-Q-tec Business Fields

In addition to commercial equipment, va-Q-tec offers comprehensive solutions for various industries. Our portfolio includes, among others, pharmaceutical logistics in the last-mile pharma segment, where we provide specialized packaging for temperature-sensitive medications. For the automotive industry, we develop innovative solutions for transport logistics. In the chemical sector, we ensure the safe handling and transport of chemicals under controlled conditions. Furthermore, we offer tailored solutions for the food industry to guarantee the safe and energy-efficient transport of temperature-sensitive products.