Kelvin Hours

KelvinHours is a statement about the degree of temperature stability that a transport solution can realistically attain.

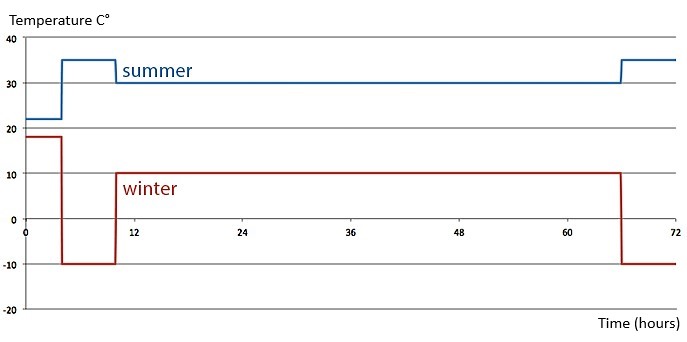

A simple comparison of qualification data under different temperature profiles does not generally provide a reliable statement. Different temperature scenarios impact thermal packaging in different ways. To allow a reliable comparison, these differences are considered in the determination of KelvinHours. They represent the best means of obtaining an objective comparison of different thermal packaging solutions. To determine the number of KelvinHours, you need two variables: the expected transport time and the expected average temperature difference to which the packaging solution will be subjected. The product of these two variables represents the number of KelvinHours.

ISTA 7D for 72 hours

This graph shows the performance of the box under standardized conditions, but it does not reflect the kind of individual loads that it can be subjected to during transport (e.g. longer transport times, more extreme peaks, longer peaks).

How can you tell if the graph presented to you reflects the actual real-world challenges?

Kelvin Hours Calculator

Example

This medicine needs to get from Berlin to Brisbane. Using the normal graph shown above we only get a standardized indication that does not account for individual factors.

Finding the thermal packaging that can maintain the medicine bottle at a temperature between 2°C to 8°C for a period of three days – at the expected external temperatures is now possible.

Use the Kelvin Hours calculator above and learn that all three shippers are able to perform for 72 hours. But only the green shipper is able to withstand the required temperature load. It is the only one with sufficient Kelvin Hours.

Only knowing the actual performance

will give you 100% planning security.

FAQs

Kelvin hours (K∙h) are a physical unit of measurement that describes the temperature difference (in Kelvin) over a certain period of time (in hours). They quantify the thermal load to which a temperature zone is exposed – and are therefore a key planning tool for temperature-controlled applications. Essentially, Kelvin hours reflect how long a product or environment has been exposed to a certain temperature. This is particularly relevant for temperature-sensitive goods, where not only the actual temperature, but also the duration of the temperature exposure is crucial for quality and effectiveness.

Kelvin hours enable the precise design of thermal solutions such as vacuum insulation panels (VIPs) or phase change materials (PCMs). Instead of working with fuzzy temperature data, K∙h can be used to make precise statements about energy absorption or release. Fluctuations within a permissible range can add up over time and still have critical effects. Kelvin hours provide a holistic view of the thermal history. They make it possible to precisely track and evaluate the actual exposure of a product to heat or cold. This helps to prevent product damage, ensure compliance with regulatory requirements and ultimately protect the integrity of your valuable goods.

Kelvin hours are an indispensable tool for risk management in the cold chain. They are ideal for designing solutions with PCMs or VIPs. They create planning security and validation transparency, especially for complex transportation or storage processes.

- Precise quality control: By accurately recording thermal exposure, potential damage to temperature-sensitive products can be detected and avoided at an early stage.

- Optimized packaging solutions: Based on Kelvin hours, packaging solutions and cooling systems can be tailored precisely to the requirements of the products and the expected transportation conditions. This minimizes oversizing and saves costs.

- Compliance and audit security: Kelvin hours provide traceable data on compliance with temperature limits over the entire transportation period – a key factor for audits and regulatory requirements.

- Increased product safety: By minimizing thermal risks, Kelvin hours make a significant contribution to ensuring the effectiveness and shelf life of your products.

The calculation is based on the formula

Kelvin hours (K∙h) = temperature difference (K) × time duration (h)

The va-Q-tec Kelvin hours calculator can be used to precisely calculate the corresponding K∙h based on the ambient temperature (°C), indoor temperature (°C) and transport duration (h). This allows you to easily simulate different scenarios.

Kelvin hours are an objective means of comparing thermal transport solutions. If you do not know the Kelvin hours of a product, ask the manufacturer, who should be able to provide you with the necessary information.

The easiest way is to contact the manufacturer. If this does not help, you can determine the Kelvin hours from the qualification data or the live shipping data. We will be happy to help you with this if you wish. Please contact us at [email protected]

Different temperature profiles can have different effects on different types of insulated packaging. Therefore, a box with fewer Kelvin hours in combination with a weaker temperature profile may achieve the same performance as a box with more Kelvin hours with a stronger profile. By taking Kelvin hours into account, this difference is eliminated. A simple comparison of these Kelvin hours shows which box meets your insulation requirements.

This is always useful if an objective performance comparison between different insulated packaging is to be carried out.

Determining the average outside temperature for a specific transport route and duration is crucial for planning your cold chain solution. Several methods are available for this: for example, temperature data loggers, historical weather data, empirical values, risk profiles or simulations.

va-Q-tec supports you with sound advice and access to relevant climate data in order to find the optimum temperature solution for your requirements.

The required Kelvin hours depend on your specific temperature profile, the desired holding time and the thermal sensitivity of your product. There is no one-size-fits-all answer – every product and every route is unique. Our experts analyze your requirement profile and develop a solution with optimum insulation or heat storage: individual, precise, efficient.

In this case, the external temperature profile does not represent any stress on the insulating packaging. It is therefore not necessary to specify Kelvin hours, as they are simply zero.