Sustainable logistics solution for Hofpfisterei

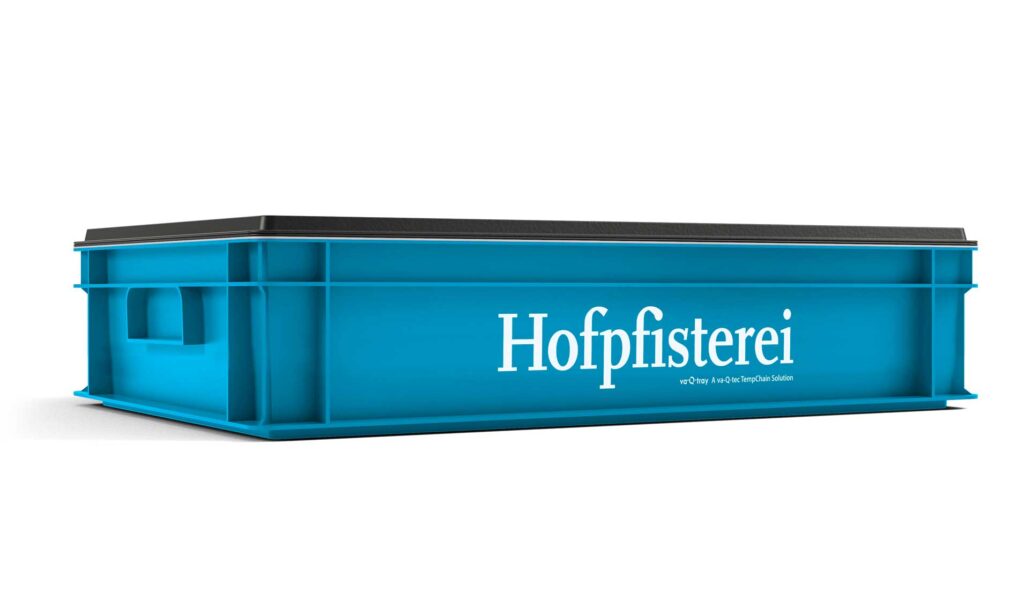

Hofpfisterei, a traditional bakery company with its roots in the heart of Munich, has always stood for quality craftsmanship, sustainable business practices and responsible use of resources. With over 140 branches, it is one of the most important bakeries in southern Germany. In order to meet these high standards in the area of logistics, Hofpfisterei has been relying on a pioneering solution since January 2022: the innovative, vacuum-insulated va-Q-tray boxes from va-Q-tec.

Sustainable and efficient transportation

with the va-Q-tray

In close cooperation with the va-Q-tec team, around 4,000 va-Q-tray M 15 boxes were specially tailored to the needs of the bakery. The challenge: the sustainable and efficient transportation of frozen pretzel dough pieces from the production site to the branches – without the use of dry ice or active refrigerated vehicles. The solution: a passively cooling transport box that reliably maintains the cold chain while making a noticeable contribution to conserving resources.

Annual savings of around 100,000 kWh of electricity

The switch to the va-Q-tray boxes is having a noticeable impact both ecologically and economically. Hofpfisterei saves around 100,000 kWh of electricity every year – a significant contribution to energy efficiency. At the same time, packaging waste is reduced by around 50 tons per year, particularly due to the elimination of disposable cardboard boxes and polyethylene film.

The newly developed logistics solution not only represents sustainable progress for Hofpfisterei, but also a significant increase in efficiency. The flexible, reusable boxes enable optimized storage and transport logistics while ensuring maximum product safety.

By using the va-Q-tray boxes, Hofpfisterei shows how tradition and innovation can be successfully combined – and how the right partnership with va-Q-tec can make a tangible contribution to greater sustainability in the food industry.