Professional Coffee Machines for the Out-of-Home Market

Increased Energy Efficiency in Continuous Operation: va-Q-tec reduces Energy Consumption of Professional Coffee Machines with Vacuum Insulation

- Significantly lower energy losses in hot water boilers during standby

- Up to 30 percent reduction in daily energy consumption

- Fast payback and more stable brewing temperatures

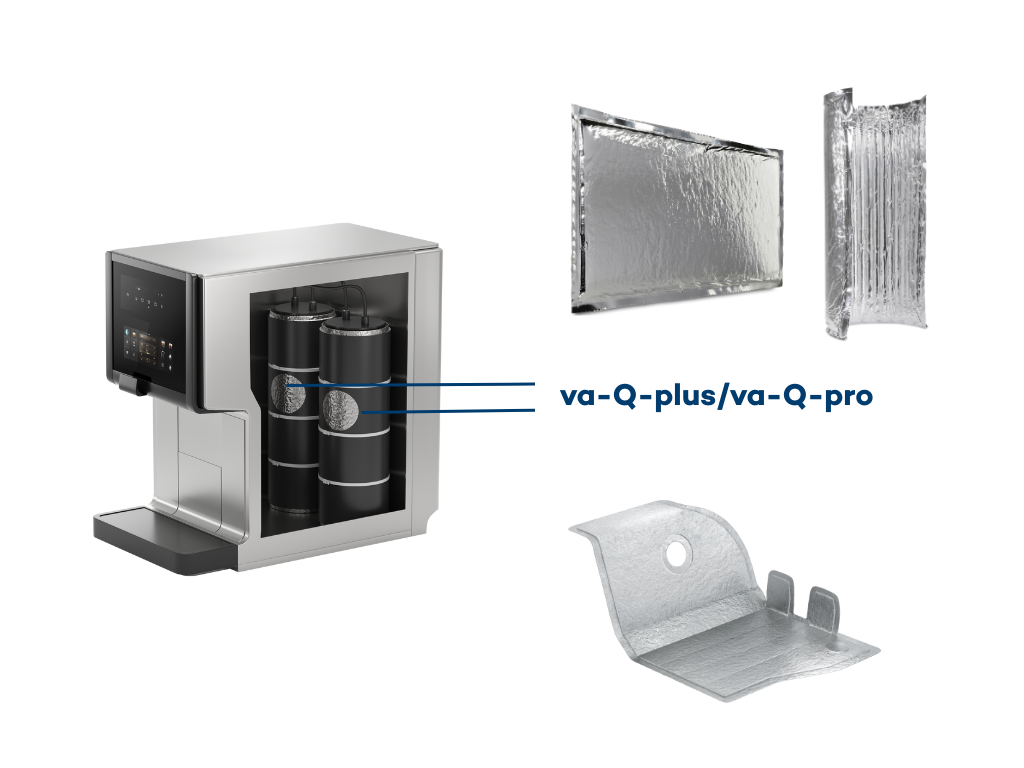

Würzburg, January 03, 2026. Professional coffee machines used in gastronomy, hospitality and contract catering are often operated continuously throughout the day. Even during periods of low demand, hot water boilers for coffee preparation must be kept at a constant temperature. This results in high energy consumption and consequently high operating costs, particularly during standby operation. To improve energy efficiency, va-Q-tec now offers its high-performance insulation with Vacuum Insulation Panels (VIPs) for use in professional coffee machines.

“Especially in coffee machines, a large proportion of energy consumption occurs outside the actual brewing process. Vacuum insulation panels can significantly reduce these losses without compromising temperature stability or coffee quality,” says Bastian Herbert, Market Director Appliances at va-Q-tec.

Reduced energy losses, stable temperatures, optimized usable volume

Thanks to space-saving vacuum insulation with a very low thermal conductivity of 0.0035 W/(m*K), the internal space of the machine is optimized. Heat losses at hot water boilers and other relevant components are significantly reduced. In real-life operation, savings of around 30 percent in daily energy consumption can be achieved. In standby mode, energy savings of approximately 30 percent are also possible. During the brewing process, energy consumption per cup is reduced by more than 20 percent.

In addition to energy savings, the improved insulation ensures stable brewing temperatures. This has a direct positive impact on beverage quality, providing an additional competitive advantage in professional applications.

Economic efficiency and sustainability

For operators of cafés, hotels, canteens or bakeries, the reduced energy consumption results in noticeably lower operating costs, particularly during long idle times. At the same time, the CO₂ footprint is reduced. Thanks to the combination of energy savings and continuous operation, the use of Vacuum Insulation Panels pays for itself in many applications within one year.

va-Q-tec’s VIP solutions can be integrated into both new developments and existing coffee machine systems. They support manufacturers and operators in combining economic efficiency, sustainability targets and consistently high coffee quality.