Laboratory Appliances

Innovative Solutions for Laboratory Appliances

For laboratory Appliances such as ultra-low-temperature freezers or incubators, precision is paramount. Our VIPs and PCMs maintain consistent temperatures even during peak loads, significantly reducing energy consumption. This enhances equipment reliability and sustainably improves efficiency in everyday laboratory operations.

Precise Temperature Stability with Minimal Wall Thickness

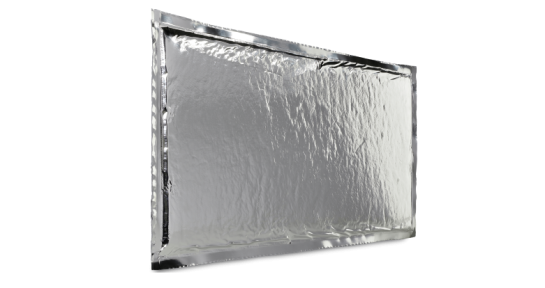

va-Q-tec combines highly efficient vacuum insulation panels (VIPs) with phase change materials (PCMs) to achieve maximum temperature stability with minimal energy consumption. The slim insulation maximizes interior volume, while PCMs reliably compensate for temperature fluctuations.

The result: efficient, safe continuous operation in ultra-low-temperature freezers, incubators, and other laboratory equipment.

Products

Maximum Efficiency

va-Q-tec solutions support these requirements through precise temperature control and optimal insulation. Vacuum insulation panels reduce heat loss with slim wall thicknesses, saving energy during standby operation, while phase change materials compensate for temperature fluctuations. Applications such as coffee machines and vending machines clearly demonstrate how precise temperature control, higher efficiency, and extended equipment lifespan provide significant advantages and cost-saving potential in daily use. Other commercial applications in gastronomy and retail also benefit from these properties.

Development & Implementation Support

To develop optimal solutions, va-Q-tec supports projects from the initial inquiry through to series production. The expertise consolidated in our Thermal Engineering Center provides support at every stage, from concept and implementation to quality assurance.

Benefits of va-Q-tec High-Performance Insulation

Our vacuum insulation panels (VIPs) are redefining the standards in refrigeration technology. From household appliances and laboratory equipment to industrial cooling systems, we provide solutions that excel both technically and economically:

Vacuum insulation panels in the appliance walls significantly extend the holdover time. In the event of a technical malfunction or power failure, valuable stored goods remain within the safe temperature range many times longer than with conventionally insulated appliances – a decisive factor in minimising risk in the laboratory.

Yes. Thanks to va-Q-pro technology, customised 2D and 3D free forms can be manufactured. This enables VIP surface coverage of up to 85%, as even complex geometries such as compressor niches or cable bushings can be precisely insulated without having to fundamentally change the existing device design.

It is the perfect combination for maximum safety: while VIPs passively minimise heat input, PCMs (phase change materials) actively buffer temperature fluctuations caused, for example, by frequent door opening during high sample removal. This guarantees constant thermal stability at the highest level.

Yes. The extreme insulation performance ensures that the outside of the enclosure remains at almost ambient temperature. This prevents the dew point from falling below the surface of the device and reliably prevents condensation from forming. This protects the hardware from corrosion and ensures compliance with the hygiene standards that are critical in laboratories.

Since VIPs offer up to ten times better insulation than conventional materials, they enable significantly thinner device walls. This significantly optimises the ratio of external dimensions to usable internal space: significantly more samples can be stored with the same footprint – an invaluable advantage when laboratory space is limited.

VIPs based on high-quality pyrogenic silica are designed for an extremely long service life. Unlike other materials, they exhibit minimal ageing effects, meaning that their thermal performance remains virtually constant throughout the entire life cycle of the laboratory equipment.

Additional va-Q-tec Business Fields

In addition to commercial equipment, va-Q-tec offers comprehensive solutions for various industries. Our portfolio includes, among others, pharmaceutical logistics in the last-mile pharma segment, where we provide specialized packaging for temperature-sensitive medications. For the automotive industry and the broader mobility sector, we develop innovative, lightweight insulation solutions that enhance energy efficiency and reduce CO₂ emissions in transport and logistics applications. Furthermore, we offer tailored solutions for the food industry to guarantee the safe and energy-efficient transport of temperature-sensitive products.