Retail

Reliable cold chains with minimal process effort

Conventional cold chains are complex, energy-intensive, and inflexible. Refrigerated vehicles with active cooling, dry ice, or bulky ice packs require high energy consumption, additional picking steps, and considerable infrastructure in distribution centers and stores. At the same time, waiting times and intermediate cooling tie up resources and reduce flexibility in daily operations.

The Thermo Trolley breaks this pattern: thanks to the use of highly efficient vacuum insulation panels (VIPs), your goods remain at a constant temperature for up to 12 hours – solely due to the thermal energy of the load itself. With just two special batteries, you can easily extend this period to 24 hours.

- 75% lower operating costs: Significant savings over the entire product life cycle.

- Simplified processes: No need for complex handling of coolants or intermediate cooling.

- Ready for immediate use: Easy loading, passive transport in standard trucks, and quick cleaning in the distribution center.

The result is a complete cold chain that radically simplifies your logistics processes while measurably supporting your climate goals.

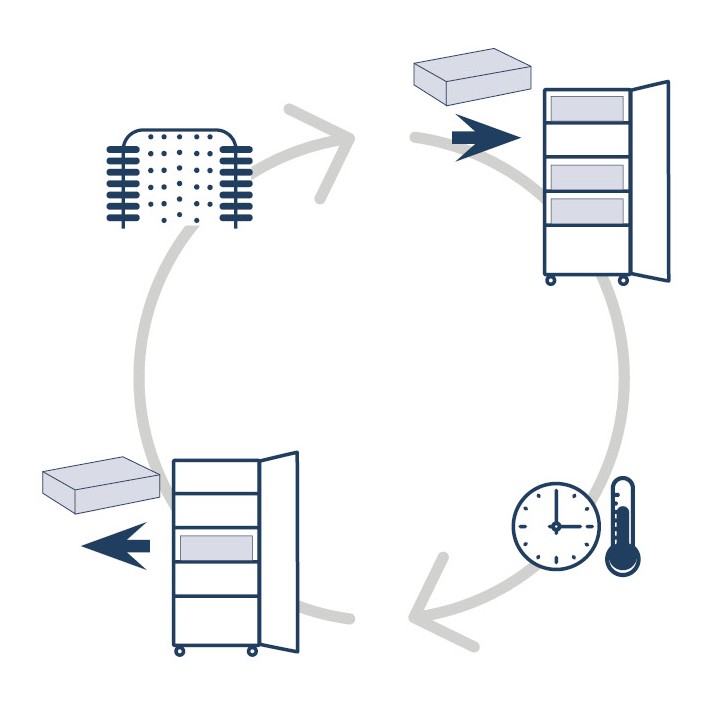

Safe and easy handling

- Goods are picked directly in the cold store using the Thermo Trolley.

- Temperature is maintained during transport without the need for electricity, active refrigerated vehicles, or dry ice.

- Food at the ideal temperature can be removed and stored.

- Return and cleaning at the distribution center; optional: service & maintenance.

- Goods are picked directly in the cold store using the Thermo Trolley.

- Temperature is maintained during transport without the need for electricity, active refrigerated vehicles, or dry ice.

- Food at the ideal temperature can be removed and stored.

- Return and cleaning at the distribution center; optional: service & maintenance.

Products

Standard specifications of the Thermo Trolley

Our Thermo Trolley offers a robust, maintenance-free solution for demanding fresh produce logistics. With a choice of casters or skids, it can be seamlessly integrated into existing processes. The high-quality organic coating protects against corrosion, while ergonomic controls and variable insertion rails guarantee efficient handling. A particular advantage is that the insulation performance of the integrated vacuum insulation panels can be validated by a service check, which increases their service life. At the end of the cycle, single-type disassembly ensures that the materials are returned to the recycling cycle.

Advantages

Market Comparison

The high-performance solution consists of a vacuum-insulated, heavy-duty thermal trolley. It represents a significant advancement over conventional solutions and offers improved cooling performance and efficiency.

Thanks to the vacuum insulation, the temperatures of the food can be kept constant for up to 12 hours without ice packs – cold or frozen. The robust design means that the system is designed for continuous daily use and remains reliable even under intensive logistical conditions.

With just two special batteries, the temperature retention period can be extended to up to 24 hours – for both frozen and fresh goods. For longer transport times, the retention period can be further increased by using additional special batteries.

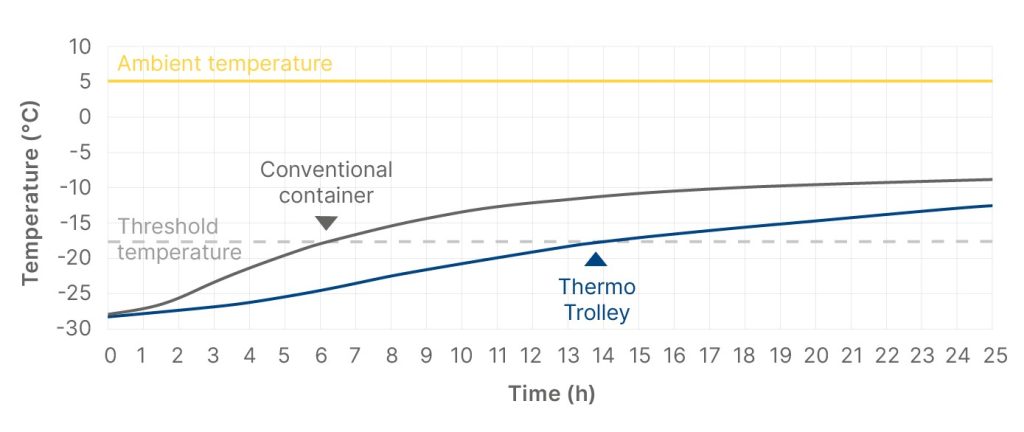

Thermo Trolley without batteries vs. conventional container

Framework conditions:

- Constant outside temperature of 5 °C

- Limit temperature -18 °C

- Load 150 kg frozen goods

The test results show that the Thermo Trolley performs twice as well as conventional containers.

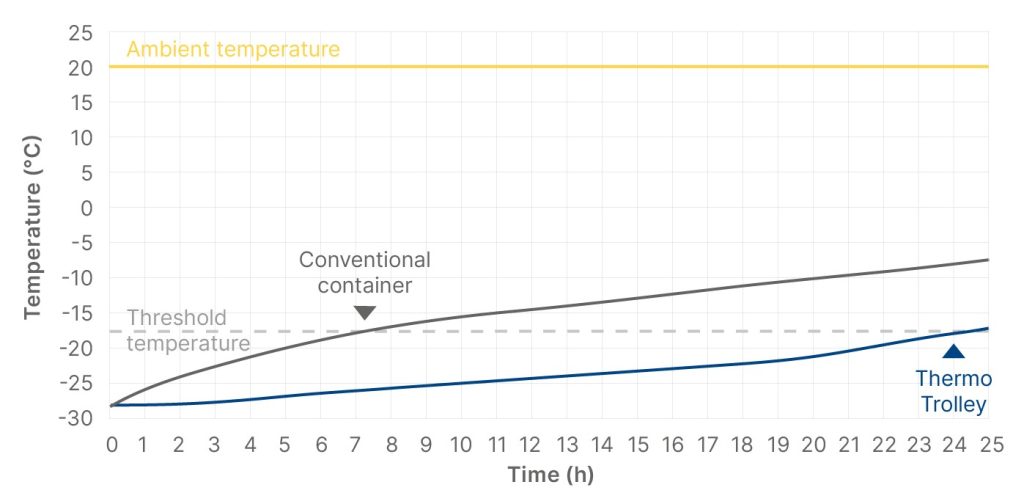

Thermo Trolley with two special batteries vs. conventional container with a corresponding number of comparable batteries.

Framework conditions:

- Constant outside temperature of 20 °C.

- Limit temperature -18 °C.

- Load 150 kg of frozen goods.

This test also shows that the Thermo Trolley achieves twice the performance of conventional containers.

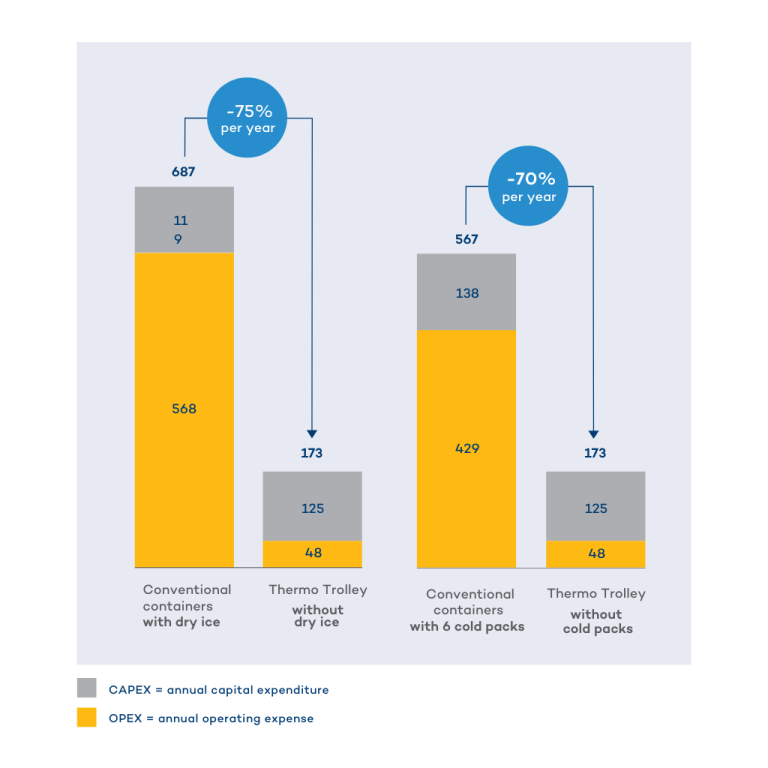

Consideration of total costs per year

The Thermo Trolley can reduce annual total costs by up to 75% while completely eliminating the need for dry ice and ice packs. The return on investment is usually achieved within approximately one year.

In addition, the Thermo Trolley offers several strategic advantages: simplification and acceleration of operational processes, high flexibility, effective support in achieving climate targets, and a durable and repairable system design.

The Thermo Trolley can reduce annual total costs by up to 75% while completely eliminating the need for dry ice and ice packs. The return on investment is usually achieved within approximately one year.

In addition, the Thermo Trolley offers several strategic advantages: simplification and acceleration of operational processes, high flexibility, effective support in achieving climate targets, and a durable and repairable system design.

FAQs

The main difference lies in the use of highly insulating vacuum insulation instead of conventional PU foam insulation, which radically simplifies logistics processes. This technology eliminates the need for dry ice, cooling packs, and special refrigerated vehicles, making daily operations more efficient. In addition, the robust and modular design ensures a longer service life and better repairability, while customers also benefit from the strong partnership between Wanzl as a design expert and va-Q-tec as a specialist in high-tech insulation.

The holding time basically depends on the desired temperature range, the load, and the ambient temperature, whereby the system keeps the temperature stable about two to three times longer than solutions from competitors in a direct comparison. As a rule, delivery times in logistics processes are strictly defined, which is why tests can often be carried out without or with significantly fewer cooling elements than usual. Test values of around 12 hours of stability without batteries and up to 24 hours when using just two handy special batteries serve as a reliable reference here.

A key advantage is the use of a corrosion-resistant steel shell instead of a simple plastic shell, which greatly increases resistance in everyday logistics. In addition, the integrated vacuum panels show significantly less aging compared to conventional PU foam, which means that the insulation performance remains stable over many years. Since the design deliberately avoids welding or bonding processes, all main components can be dismantled and easily replaced individually if necessary.

Due to the robust construction and consistent use of steel, a significantly longer service life than market competitors is expected on average, with values of around 12 years being achieved as standard compared to the usual 8 years. A decisive factor here is that the insulating performance of the vacuum panels hardly decreases over this long period. In contrast, classic PU foam insulation often shows very rapid aging, with performance dropping to around 80% after just two years.

The system is fully suitable for food transport, as the plastic material used meets all relevant hygiene and safety standards. The one-piece inlay has also been designed with rounded corners and edges and a smooth surface to effectively prevent dirt from sticking. This makes cleaning particularly easy and thorough, ensuring long-term hygiene and safety in the daily handling of sensitive goods

To ensure maximum safety, the customer’s specific process can first be replicated one-to-one in the laboratory in order to qualify performance even under worst-case conditions. In addition, it is possible to track temperatures on a random basis during the introductory phase in order to confirm the thermal values in practice. Comprehensive, long-term tracking of each individual trolley is usually not economically viable due to the high additional costs for sensors, process implementation, and regular calibration, and is generally not necessary given the stable passive insulation performance.

Other business areas of va-Q-tec

In addition to the Thermo Trolley, va-Q-tec offers comprehensive solutions for various business areas. These include highly efficient solutions for commercial appliances such as refrigerated display cases and vending machines. Our portfolio also includes pharmaceutical logistics in the last-mile pharmaceutical sector, where we provide special packaging for temperature-sensitive medicines. For the automotive industry, we develop innovative solutions for transport logistics. In addition, we offer tailor-made solutions for the food industry to ensure the safe and energy-efficient transport of temperature-sensitive products.